Neodymium Magnet Coating & Plating

2024-10-31

Neodymium Iron Boron (NdFeB) magnets are among the strongest permanent magnets, widely used in industrial applications due to their high magnetic energy and durability. However, NdFeB magnets are inherently vulnerable to corrosion, requiring protective coatings to maintain performance and longevity. This article explores the most common coating options, their unique benefits, and ideal use cases for maximizing magnet efficiency in various environments.

Common Coating Types for NdFeB Magnets

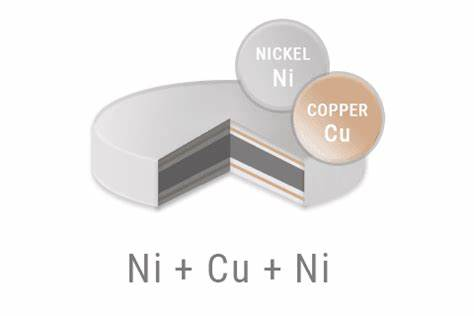

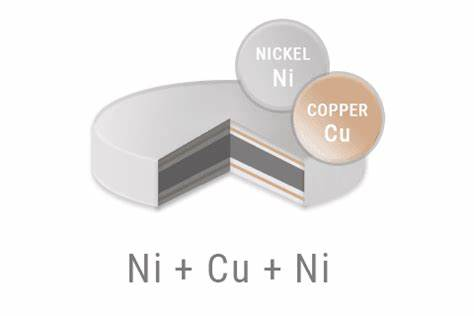

1. Nickel (Ni-Cu-Ni) Coating

Properties: Nickel is the most commonly used coating for NdFeB magnets, offering excellent corrosion resistance and durability. With a triple-layer (nickel-copper-nickel) structure, it provides a protective barrier against moisture and minor abrasions.

Applications: Ideal for general industrial uses and where durability and corrosion resistance are critical. It's a versatile option that is both cost-effective and widely applicable.

Properties: Nickel is the most commonly used coating for NdFeB magnets, offering excellent corrosion resistance and durability. With a triple-layer (nickel-copper-nickel) structure, it provides a protective barrier against moisture and minor abrasions.

Applications: Ideal for general industrial uses and where durability and corrosion resistance are critical. It's a versatile option that is both cost-effective and widely applicable.

2. Zinc (Zn) Coating

Properties: Zinc coating is a cost-effective option with a self-sacrificial property, which means it oxidizes over time to form a protective layer that prolongs the magnet's life.

Applications: Frequently used in motor assemblies and other industrial applications where cost is a concern, and minor exposure to moisture is expected.

3. Epoxy Coating

Properties: Epoxy coatings offer excellent resistance to humidity, salt, and acidic environments, providing a smooth, non-conductive layer over the magnet.

Applications: Commonly used in electronics, offshore, and high-humidity environments due to its resilience. However, epoxy can be prone to chipping, making it less suitable for applications where impact is common.

4. Teflon (PTFE) Coating

Properties: Teflon coatings offer high resistance to chemicals, making them suitable for harsh environments with exposure to strong acids or alkalis. However, the thick layer can reduce magnetic force slightly.

Applications: Ideal for chemical processing and food industries, where resistance to aggressive chemicals or non-stick properties is critical.

Each coating has specific advantages suited to different applications, and selecting the correct one maximizes both magnet performance and longevity. By understanding these options, businesses can ensure optimal magnet performance and a longer service life tailored to their operational needs.

Contact our expertise to discuss your needs for neodymium magnet coatings.

E: sales@core-magnets.com