Tips for Purchasing Neodymium Magnets

Purchasing neodymium magnets can be challenging due to their wide variety of applications, grades, and specifications. Selecting the right magnet for your needs ensures optimal performance and cost efficiency. In this guide, we provide essential tips to help you make an informed decision when buying NdFeB magnets, tailored to your project or business requirements.

Understand Your Application Requirements

Before purchasing, clearly define the magnet's application. Consider factors such as:

- Strength requirements: Do you need high magnetic force for industrial use or a less powerful option for consumer products?

- Environmental conditions: Will the magnet face high temperatures, moisture, or corrosive environments?

For instance, applications in motors or generators may require N52-grade neodymium magnets, while simpler applications like closures may only need N35-grade magnets.

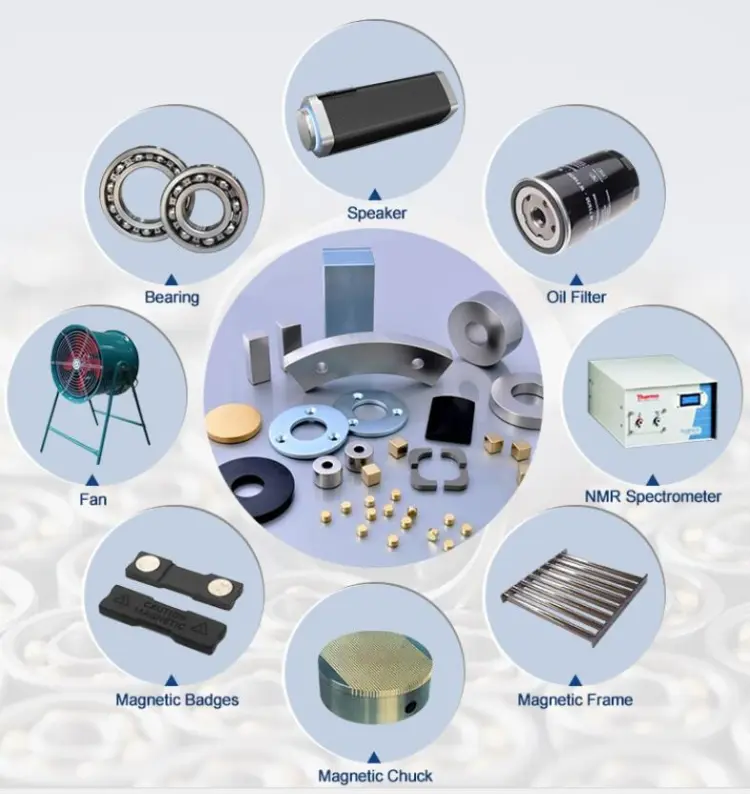

Choose the Right Shape and Size

Common shapes include disc magnets, block magnets, ring magnets, and cylindrical magnets. The size and shape directly affect performance and compatibility with your design.

- Disc magnets are ideal for sensors and small assemblies.

- Block magnets are commonly used in industrial and engineering applications.

- Ring magnets are perfect for rotational or mounting applications.

Always ensure that the magnet's dimensions and tolerances match your project's specifications.

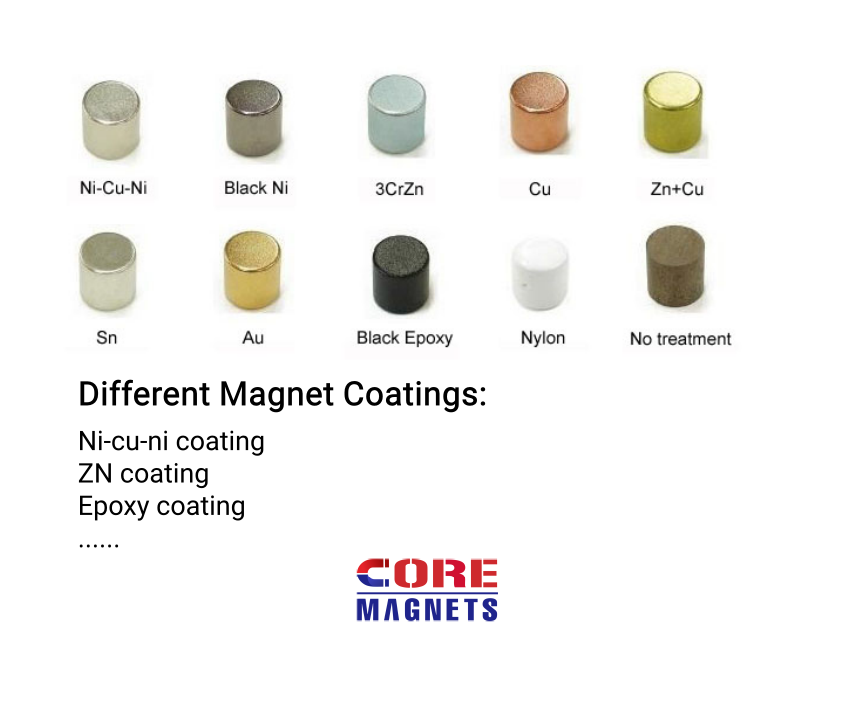

Select the Appropriate Coating

Neodymium magnets are prone to corrosion and oxidation, so selecting the right coating is essential. Popular coatings include:

- Nickel-Copper-Nickel: Provides durability and a polished finish.

- Epoxy: Offers enhanced resistance to moisture.

- Gold: Ideal for medical or aesthetic applications.

Verify the Magnet Grade

The magnet grade (e.g., N35, N48, N52) indicates its strength. Higher grades have stronger magnetic fields but may cost more. Match the grade to your application's specific needs to avoid overpaying for unnecessary performance.

Evaluate Temperature Resistance

Temperature resistance varies by grade and coating. If your application involves high temperatures, consider purchasing high-temperature neodymium magnets, such as the AH or SH series, which maintain their performance at elevated temperatures.

Purchase from a Reliable Supplier

Working with a trusted supplier ensures quality, consistency, and compliance with industry standards. When evaluating suppliers, look for:

- Certifications: ISO 9001 or other quality certifications.

- Customization options: Ability to meet specific design and tolerance needs.

- After-sales support: Clear return policies and technical assistance.

Check Packaging and Shipping Requirements

Neodymium magnets are fragile and require proper packaging to prevent damage during transit. Ensure that the supplier uses secure packaging and complies with shipping regulations for magnets.

Compare Prices and Bulk Order Benefits

When buying magnets, especially for industrial use, compare prices from multiple suppliers and inquire about bulk order discounts. However, avoid compromising quality for lower costs.

Purchasing neodymium magnets requires careful consideration of application requirements, grades, shapes, coatings, and supplier reliability. By following these tips, you can make an informed decision, ensuring that your magnets deliver optimal performance and value.

Contact us today to find the perfect neodymium magnets for your project!

Email: sales@core-magnets.com

WhatsApp: 86 180 2525 1110