Plating Process for Neodymium Magnets

Why Plating is Essential for Neodymium Magnets

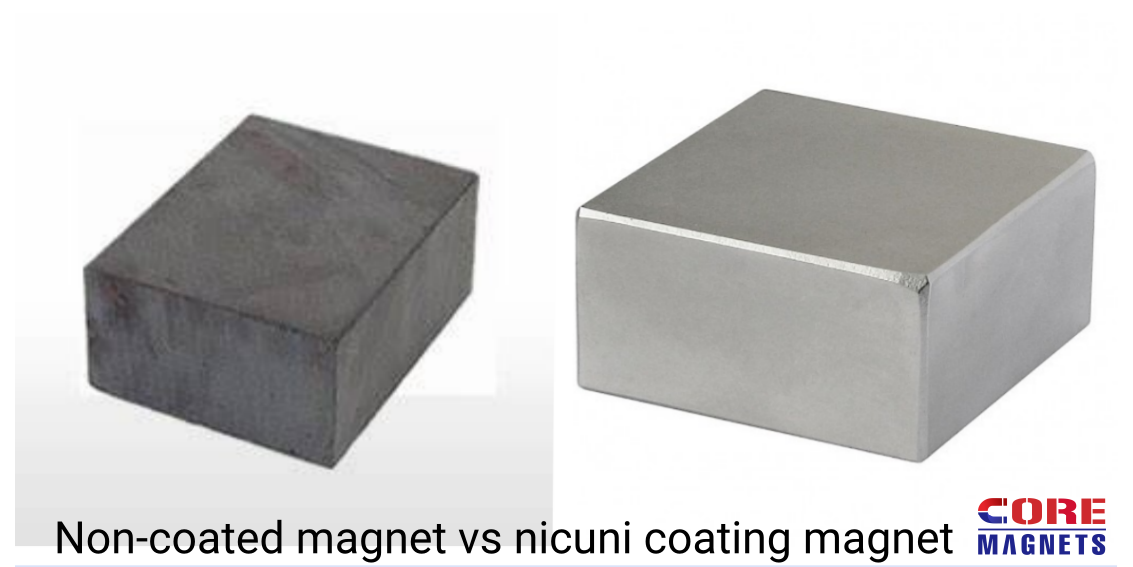

Neodymium magnets have a high magnetic strength but are prone to corrosion, especially in humid or high-moisture environments. Without a protective coating, these magnets can degrade quickly, reducing their performance and durability. Plating serves as a protective barrier, safeguarding the magnet's surface from oxidation, wear, and chemical reactions, thus enhancing its longevity and effectiveness.

The Plating Process for Neodymium Magnets

-

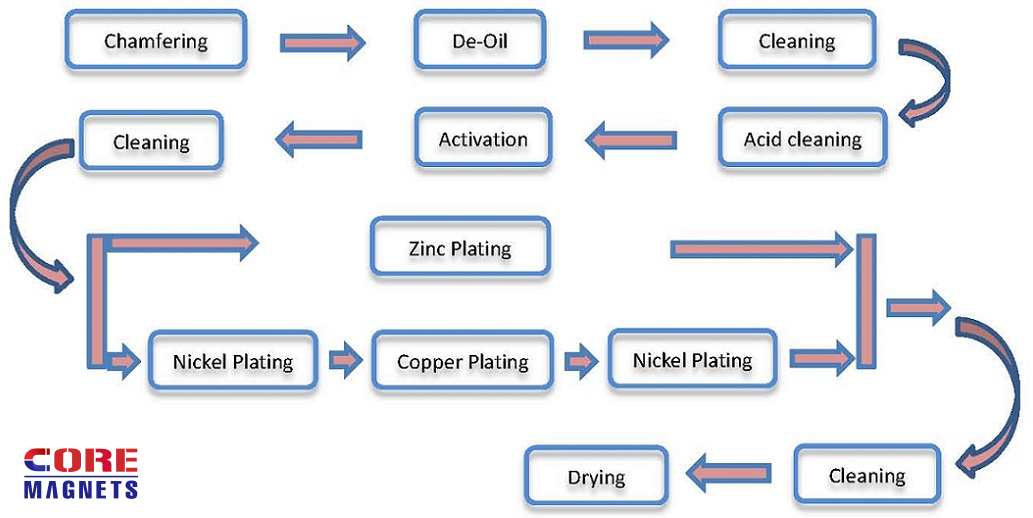

Surface Preparation

- The magnet surface must be thoroughly cleaned and polished to remove any impurities. This is achieved through processes like sandblasting or acid etching, which create a smooth surface for optimal coating adhesion.

-

Undercoat Application

- An undercoat (usually copper) is applied to improve adhesion between the magnet and the main plating material. The copper layer also adds additional corrosion resistance.

-

Main Coating Application

- The primary plating material, such as nickel or zinc, is applied through an electroplating or chemical plating process. This layer serves as the main protection barrier for the magnet.

-

Final Inspection and Quality Control

- After plating, the magnets are inspected for coating uniformity and thickness to ensure quality standards. This step is critical for magnets used in high-performance applications where consistency is essential.

Choosing the Right Plating for Your Application

The choice of plating depends on factors like operating environment, application requirements, and budget. For example, nickel plating is excellent for general corrosion protection, while epoxy and gold coatings are suitable for humid or chemical-heavy environments.

Please contact our expertise to discuss your needs, we'd be happy to support.

E: sales@core-magnets.com