Neodymium Magnets in Magnetic Couplings

Magnetic couplings, known for their ability to transfer torque without direct contact, are indispensable in industries where reliability, efficiency, and reduced maintenance are critical. At the heart of these couplings are neodymium magnets, the most powerful permanent magnets available today. This blog explores how neodymium magnets are used in magnetic couplings, their benefits, and how customized solutions can optimize your applications.

What Are Magnetic Couplings?

Magnetic couplings use magnetic fields to transmit torque between two shafts without physical connection. They are widely used in applications requiring:

- Seamless motion transfer in harsh or sealed environments.

- Elimination of wear and tear caused by friction.

- Enhanced safety and longevity in high-precision machinery.

Neodymium magnets, with their unparalleled strength, ensure that magnetic couplings can handle high torque demands while maintaining efficiency.

Why Choose Neodymium Magnets for Magnetic Couplings?

1. High Magnetic Strength

Neodymium magnets, also known as NdFeB magnets, are the strongest rare-earth magnets. This allows for compact couplings capable of handling significant loads.

2. Resistance to Demagnetization

Neodymium magnets retain their magnetic properties even under challenging conditions, ensuring consistent performance.

3. Customizable Designs

From different grades (N35 to N52) to coatings (nickel, epoxy), neodymium magnets can be tailored to specific operational needs.

4. Applications Across Industries

- Pumps and compressors: Non-contact torque transmission for liquids and gases.

- Sealed systems: Ideal for environments requiring leak-proof operations.

- High-precision machinery: Minimizing vibration and ensuring stability.

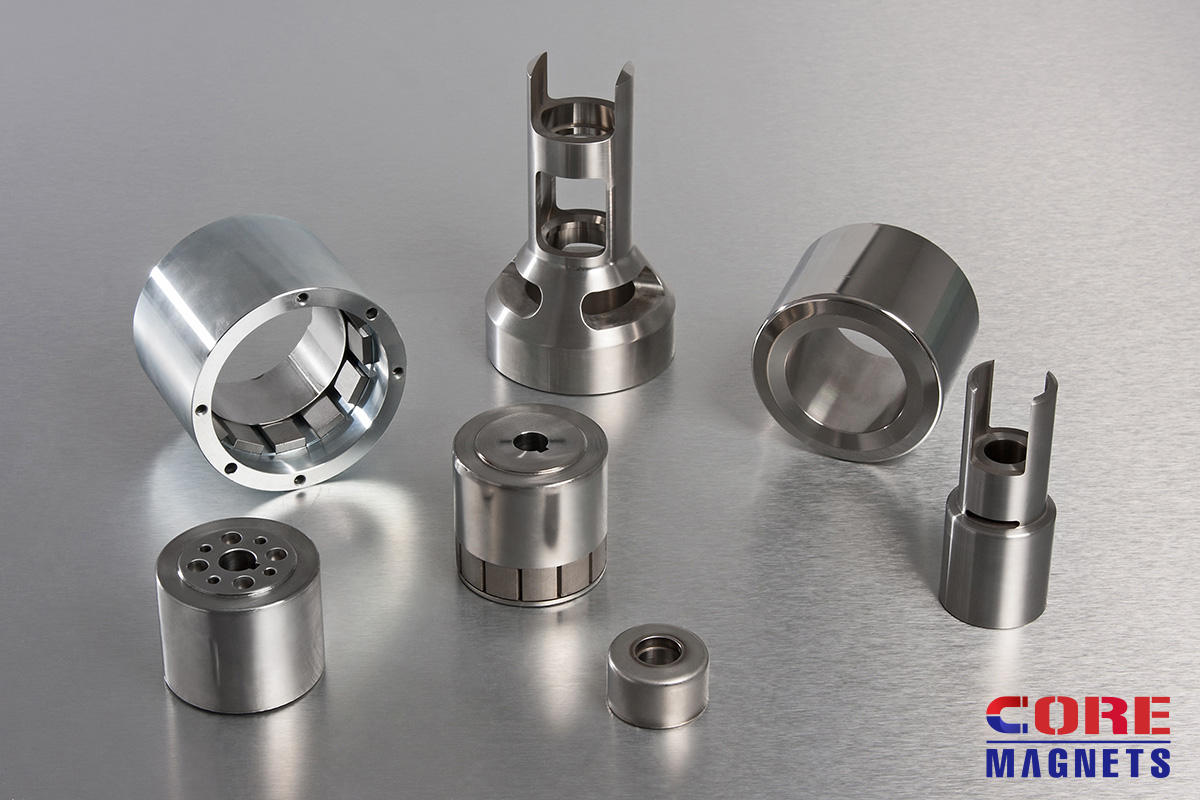

Customization Options for Magnetic Couplings

To achieve optimal performance, it's essential to customize the neodymium magnets for your specific application. Consider these factors:

- Shape and Size: Disc, ring, or custom geometries to fit your design.

- Coating Options: Protect against corrosion in harsh environments with options like nickel or Teflon.

- Magnetization Directions: Axial, radial, or custom configurations for specific torque requirements.

How to Choose the Right Neodymium Magnet for Your Magnetic Coupling?

When selecting neodymium magnets for magnetic couplings, consider:

- Operational Temperature: High-performance grades like N48H and N52H can withstand elevated temperatures.

- Torque Requirements: Ensure the magnet's strength aligns with your application's load.

- Environmental Conditions: Opt for corrosion-resistant coatings in marine or chemical environments.

Advantages of Neodymium Magnet Magnetic Couplings

- Contactless Operation: Reduces wear, noise, and maintenance.

- Improved Efficiency: Minimal energy loss during torque transmission.

- High Reliability: Withstands harsh environments and ensures long-term stability.

Industries Benefiting from Magnetic Couplings

- Pharmaceutical and Medical Equipment: Sterile and contamination-free processes.

- Chemical Processing: Leak-proof systems for hazardous substances.

- Automotive Engineering: Advanced drive systems for hybrid and electric vehicles.

Neodymium magnets are the cornerstone of magnetic couplings, offering unmatched performance and reliability in various industrial applications. With the ability to customize for your unique needs, they provide the perfect solution for high-efficiency, contactless torque transfer.

Whether you’re designing a new system or upgrading existing machinery, our team can provide tailored neodymium magnets to elevate your magnetic coupling solutions.

Contact us today to discuss your custom magnetic coupling needs!Email: sales@core-magnets.com

WhatsApp: 86 180 2525 1110