Magnet Dimensional Tolerances: Why It Matters

Dimensional tolerances are critical for ensuring the precision, reliability, and compatibility of neodymium magnets in industrial and commercial applications. Tolerances dictate the allowable deviations in magnet dimensions, ensuring that your magnets fit seamlessly into your design and function as intended. This guide provides insights into the importance of tolerances in NdFeB magnets, the standard tolerances for different shapes, and key factors to consider when specifying tolerances for your custom magnet applications.

What Are Dimensional Tolerances?

Dimensional tolerances refer to the acceptable range of variation in the size of a magnet, such as its diameter, thickness, or width. These tolerances are vital for applications where:

- Precise assembly is required.

- Tight performance specifications must be met.

- Consistency across large production runs is essential.

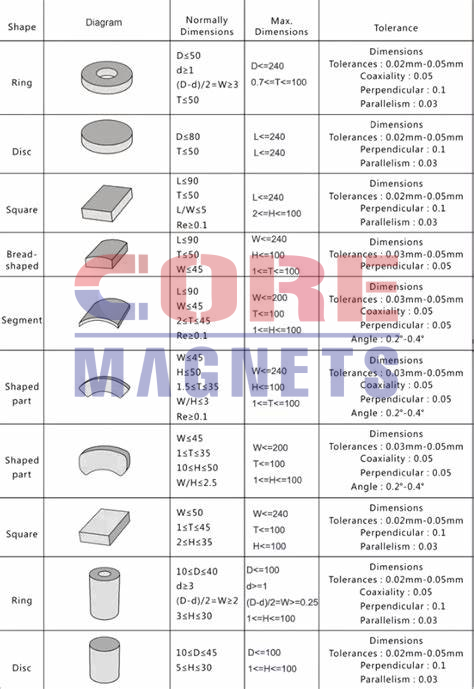

Standard Tolerances for Neodymium Magnets

1. Disc and Cylinder Magnets

- Diameter: ±0.05 mm to ±0.1 mm

- Thickness: ±0.05 mm to ±0.1 mm

2. Block and Rectangular Magnets

- Length, Width, and Height: ±0.1 mm to ±0.2 mm

3. Ring Magnets

- Outer Diameter: ±0.1 mm

- Inner Diameter: ±0.1 mm

- Thickness: ±0.1 mm

These tolerances may vary based on the manufacturing process, magnet grade, and your specific application requirements.

Why Are Tolerances Important?

- Ensuring Compatibility

Precise tolerances allow magnets to fit seamlessly into assemblies, reducing installation time and improving performance.

- Consistency Across Production

Tight tolerances ensure uniformity, especially in applications requiring mass production, such as motors, sensors, and medical devices.

- Enhanced Performance

Accurate tolerances reduce gaps, misalignments, and inefficiencies, optimizing magnetic field strength and stability.

Factors Affecting Dimensional Tolerances

- Magnet Shape and Size: Smaller magnets generally require tighter tolerances due to their application in high-precision environments.

- Material Grade: Higher-performance grades like N48 and N52 may have stricter tolerance standards.

- Coating Thickness: Coatings like nickel, epoxy, or gold add additional dimensions that must be accounted for in the tolerance range.

- Manufacturing Process: Cutting, grinding, and plating processes can affect final dimensions.

Applications Requiring Tight Tolerances

- Electric Motors and Generators: Precise tolerances ensure optimal torque and energy efficiency.

- Sensors and Actuators: Consistency in dimensions guarantees accurate readings and movements.

- Medical Equipment: Tight tolerances are critical in MRI machines and other diagnostic tools.

- Aerospace and Automotive Industries: High-performance applications demand unparalleled precision.

Dimensional tolerances are a fundamental aspect of neodymium magnet manufacturing, directly influencing their performance, reliability, and application. By understanding standard tolerances and the customization options available, you can ensure your magnets meet the highest standards of precision and quality.

Contact us today to discuss your custom tolerance requirements and find the perfect neodymium magnets for your project.

Email: sales@core-magnets.com

WhatsApp: 86 180 2525 1110