How to Clearly Specify Your Neodymium Magnet Requirements

How to Clearly Specify a Neodymium Magnet Procurement Requirement

When purchasing neodymium magnets, clear communication with your supplier is essential to avoid delays and ensure that the product meets your requirements. This guide will help you outline your needs effectively, covering both technical specifications and project delivery requirements.

1. Key Magnet Specifications

Providing detailed specifications is crucial to obtaining accurate quotes and avoiding misunderstandings. Here are the essential aspects to include:

1.1 Performance Requirements

Define the grade of the magnet required. Neodymium magnets have various grades, each indicating different levels of magnetic strength and thermal resistance.

- Specify remanence (Br) and intrinsic coercivity (Hcj) to ensure compatibility with your application.

- If the grade is unclear, provide alternative measurements such as surface magnetic flux density, pull force, or magnetic flux/moment.

- Consider environmental factors like temperature and request additional details such as temperature coefficients for Br and Hcj if applicable.

- If specific magnetic flux values are critical, agree on testing equipment and methods in advance.

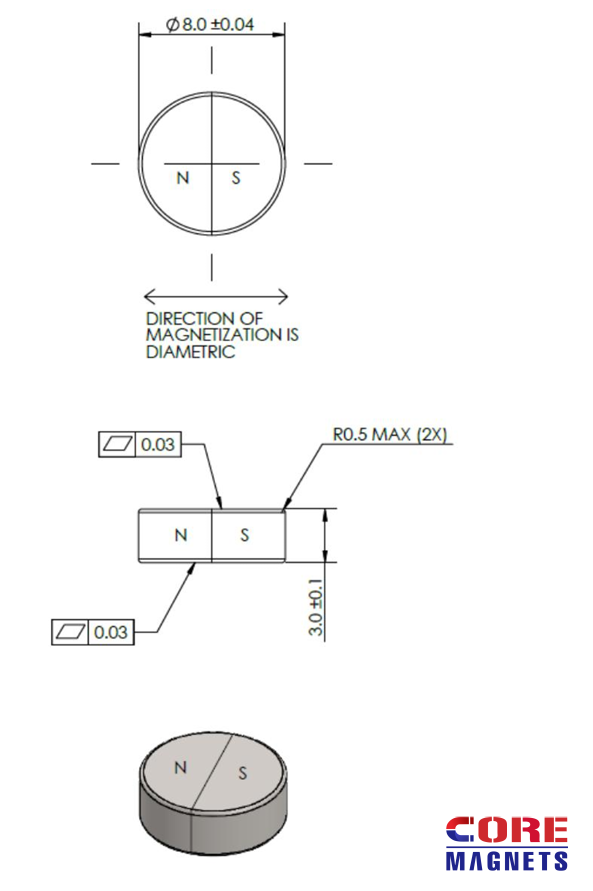

1.2 Shape, Dimensions, and Magnetization Direction

Accurately describe the shape, size, and magnetization direction.

- For simple designs, provide dimensions (e.g., 6.0mm ± 0.03mm) along with tolerances.

- For complex designs, include comprehensive drawings with detailed annotations (e.g., angles, profiles).

- Specify magnetization direction (e.g., along the height, diameter) and type (e.g., single pole or multipole).

1.3 Surface Treatment Requirements

Surface treatments protect magnets from corrosion and improve performance. Specify:

- Coating type (e.g., nickel, zinc, epoxy, or aluminum).

- Coating thickness.

- Durability requirements, such as salt spray test conditions (e.g., hours of exposure, judgment criteria).

1.4 Additional Requirements

Address any other specific needs, such as:

- Appearance standards (e.g., scratches, blemishes).

- Additional testing requirements (e.g., aging tests, vibration tests).

- Packaging and transportation requirements.

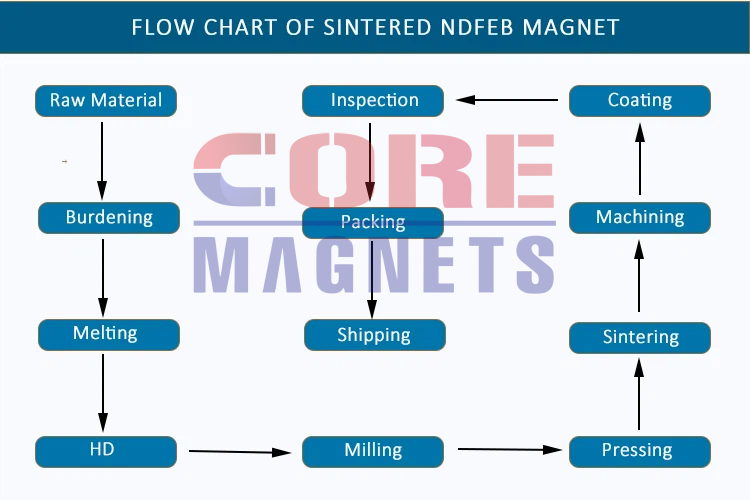

2. Delivery Timeline Considerations

Understanding production timelines can help you set realistic expectations:

- Suppliers often stock raw materials for standard grades but may need extra time for custom shapes or specifications.

- Custom designs typically require mold production, which can extend lead times.

- Discuss lead time constraints early, especially for urgent projects, and place orders promptly to avoid delays.

3. Benefits of Clear Communication with Suppliers

By providing detailed and precise information, you:

- Minimize back-and-forth communication.

- Reduce the risk of errors or mismatches in specifications.

- Obtain accurate quotes faster.

- Ensure smooth production and on-time delivery.

E: sales@core-magnets.com

WhatsApp: 86 180 2525 1110