How to Choose the Right Neodymium Magnet for Your Project

Neodymium magnets (NdFeB magnets) are powerful permanent magnets made from an alloy of neodymium, iron, and boron. Known for their exceptional magnetic strength, these magnets are widely used in various industries, including electronics, automotive, medical devices, and renewable energy systems. However, selecting the right neodymium magnet for your project can be challenging if you're not familiar with the key factors that influence magnet performance.

In this guide, we will walk you through the essential considerations for choosing the right neodymium magnet based on magnetic strength, size, shape, coating, and temperature tolerance.

Magnetic Strength (Grade and Pull Force)

The first factor to consider when selecting a neodymium magnet is its magnetic strength, which is typically measured in terms of the magnet's grade and its pull force.

- Grade: The grade of a neodymium magnet refers to its magnetic strength, with higher grades indicating stronger magnets. For example, N52 is one of the strongest grades of neodymium magnets, offering a maximum energy product of up to 52 MGOe (Mega Gauss Oersteds). The higher the grade, the stronger the magnet, which is essential for applications requiring high magnetic force.

- Pull Force: This refers to the amount of weight the magnet can lift or hold. The pull force depends on the size and shape of the magnet. Make sure to choose a magnet with sufficient pull force to meet the needs of your project.

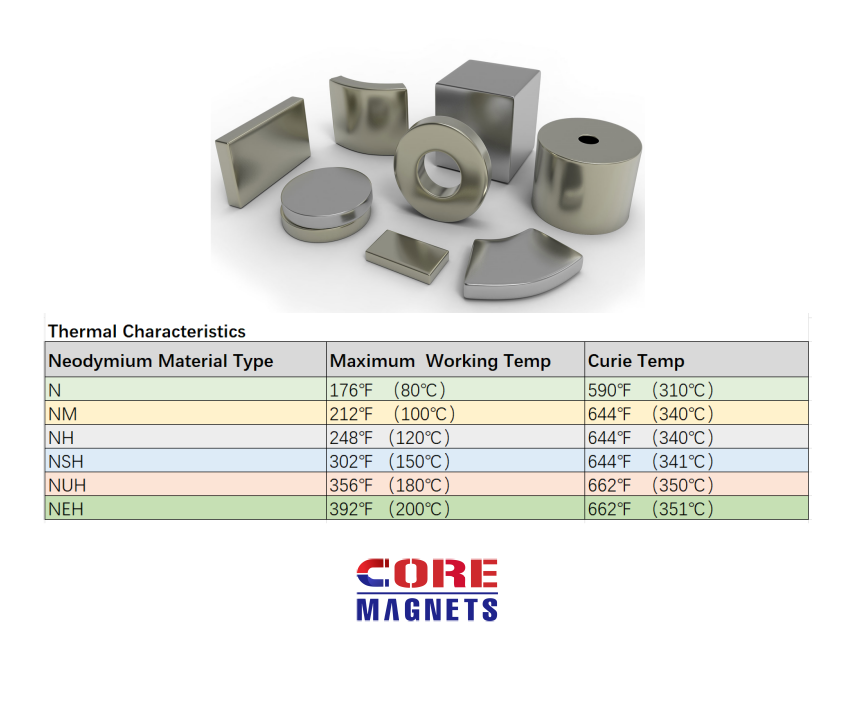

Size and Shape

Neodymium magnets come in a variety of sizes and shapes, from small disks and rings to larger blocks and custom shapes. Choosing the right size and shape depends on your project requirements.

- Size: The size of the magnet will influence both its magnetic strength and the amount of space it occupies in your application. Larger magnets generally offer more pull force but can be harder to integrate into compact spaces. If you're working on a project that requires precise positioning, smaller magnets may be more suitable.

- Shape: Neodymium magnets are available in many shapes, including:

- Discs

- Rings

- Blocks

- Cylinders

- Countersunk

- Custom Shapes

Each shape serves a different purpose. For example, discs are commonly used in motors, while rings are ideal for applications like magnetic couplings.

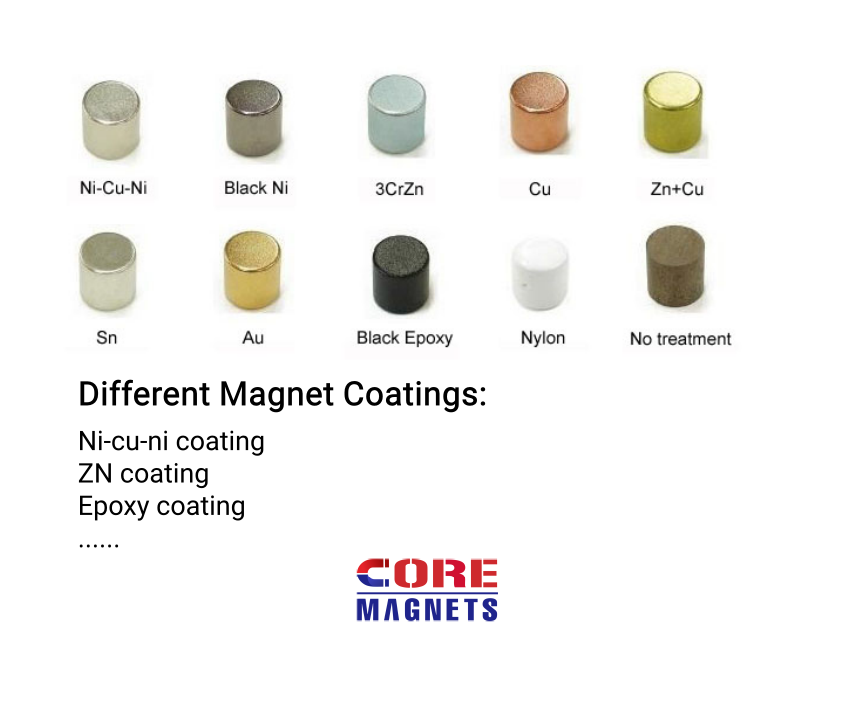

Coating and Surface Protection

Neodymium magnets are typically coated to protect them from corrosion and damage, as they are prone to oxidation when exposed to air or moisture. Common coatings include:

- Nickel (Ni): The most common coating, offering good corrosion resistance and a smooth surface.

- Zinc (Zn): Offers protection against corrosion, but not as durable as nickel.

- Epoxy: A more durable coating, ideal for harsh environmental conditions.

- Gold and Silver: Primarily used for aesthetic purposes or in high-end applications.

If your magnets will be exposed to extreme weather, chemicals, or high temperatures, consider a coating that offers superior protection.

Temperature Tolerance

Temperature can significantly affect the performance of neodymium magnets. Most neodymium magnets are rated for use within a certain temperature range. Exposing magnets to temperatures higher than their maximum operating temperature can cause them to lose their magnetic properties.

- Standard Temperature Tolerance: Neodymium magnets generally perform well up to 80°C (176°F), but specialized magnets can withstand much higher temperatures, such as 120°C (248°F), or even up to 200°C (392°F) for high-temperature magnets.

- If your project involves high-temperature environments, you should choose magnets designed for high-temperature applications, as they will retain their magnetic strength over time.

Environment and Application

Finally, consider the environment in which the magnet will be used. Neodymium magnets are ideal for dry, controlled environments but may need special coatings or alloys to perform well in harsh conditions such as exposure to moisture, chemicals, or extreme temperatures. If your project involves outdoor or industrial use, ensure that the magnet you select is compatible with your specific environment.

Order Right Magnets for Your Project Today

Ready to get started on your next project? Need to order a large number of magnets for manufacturing?

Need help choosing the right magnet for your project or do you wish to order a complete custom design?

Just give us an email and we will be happy to support: sales@core-magnets.com