The Difference Between Curie Temperature and Working Temperature of Neodymium Magnets

Magnets are essential components in various industries, but did you know that excessive heat can cause them to lose their magnetic properties permanently? Two critical parameters—Curie temperature (Tc) and working temperature (Tw)—play a vital role in determining the thermal stability and performance of neodymium magnets. Let’s explore these terms and how they relate to selecting the right magnets for your applications.

What is Curie Temperature?

The Curie temperature, named after physicist Pierre Curie, is the threshold temperature where magnetic materials transition from a ferromagnetic state to a paramagnetic state. Below this temperature, the material exhibits strong magnetism, but once surpassed, the magnet's internal molecular structure changes, leading to irreversible demagnetization.

Key points about Curie temperature:

- Definition: It’s the temperature at which a material's magnetic properties cease due to molecular disruption.

- Impact: When heated beyond the Curie temperature, the magnet requires a much higher magnetic field to regain its properties, and the recovered magnetic strength may not match its original performance.

- Relevance: Selecting materials with a suitable Curie temperature ensures reliability in high-temperature environments.

For neodymium iron boron (NdFeB) magnets, the addition of elements like cobalt, terbium, and dysprosium can increase the Curie temperature, enhancing thermal stability.

What is Working Temperature?

The working temperature of a magnet refers to the maximum temperature it can withstand in real-world applications without significant, irreversible loss of magnetic properties.

Key insights:

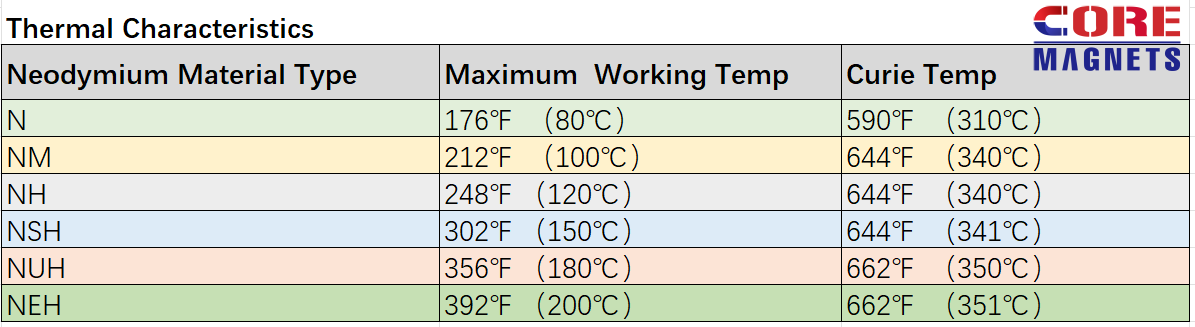

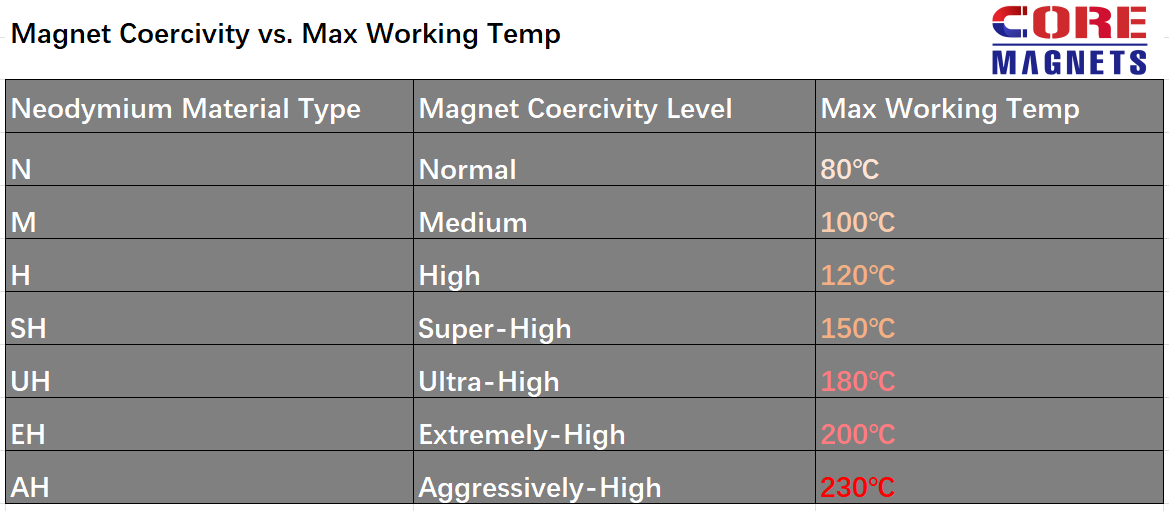

- Range: The working temperature of neodymium magnets is generally much lower than their Curie temperature. It typically falls between 80°C and 230°C, depending on the grade and composition.

- Factors influencing working temperature:

- Shape and size: The length-to-diameter ratio (or permeance coefficient, Pc) significantly affects the maximum working temperature.

- Magnetic circuit design: A more closed magnetic circuit increases thermal stability, allowing the magnet to function at higher temperatures without demagnetization.

- Materials: Higher-grade magnets with enhanced coercivity, such as H or SH series, are designed to perform better in elevated temperatures.

The Role of Coating in Thermal Performance

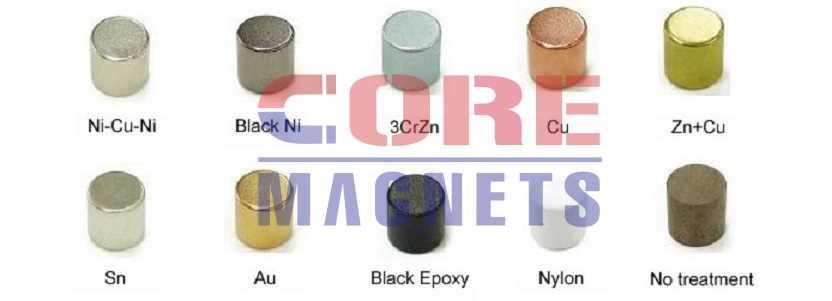

Magnet coatings also impact thermal performance. They:

- Protect magnets from oxidation and corrosion, which can worsen under high temperatures.

- Ensure longevity in applications where thermal cycling is frequent.

Common coatings for neodymium magnets include nickel-copper-nickel (Ni-Cu-Ni), epoxy, and Parylene. These coatings not only enhance durability but also contribute to maintaining magnetic properties in demanding environments.

Contact our expertise to discuss your needs, we will support you with professional knowledges and competitive pricings.

E: sales@core-magnets.com

WhatsApp: 86 180 2525 1110